Tank Sensor

Tank Sensor HVAC Sensors

HVAC Sensors Electronic scales sensors

Electronic scales sensors

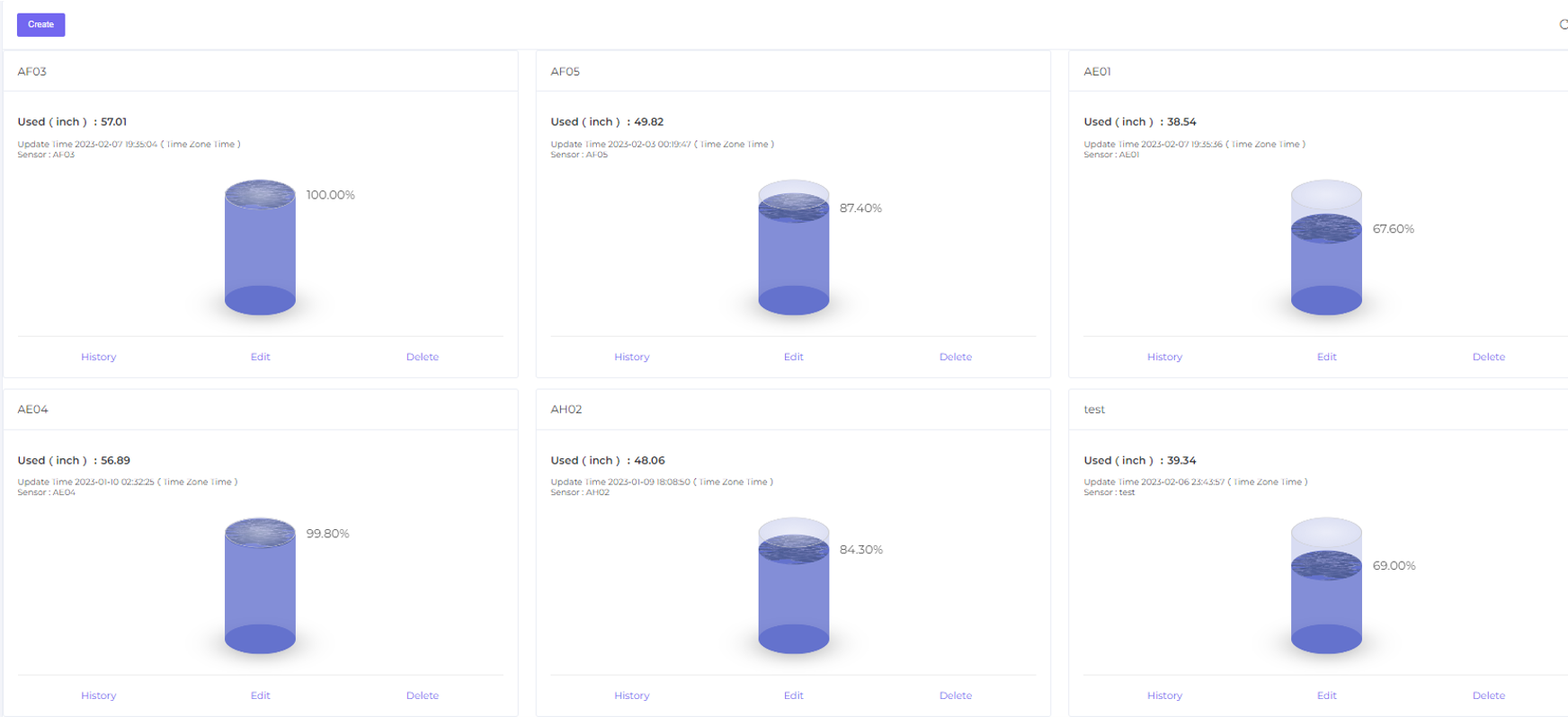

Sensor Detection System:

It provides real-time alerts when it detects that the container is full.

Simple Interface: The website

interface presents the container's status using a percentage mode.

Waste Liquid Recovery Guidance:

It can guide waste recovery companies to collect waste from the container when it's full.

Simultaneous Detection of Multiple Sensors:

The system on the website can simultaneously monitor multiple containers (up to 1000).

Easy Operation and Viewing:

The sensor website can be accessed via mobile phones, tablets, or computers for real-time monitoring of container status.

Sensor Recording:

It accurately records the liquid level inside the container at different times.

Adjustable Detection Height:

It can be adjusted according to the height of different containers.

Customizable Time Zone:

Time adjustments can be made according to different time zones.

| Sensors height | 20cm |

| Measure height | 20 cm to 8 meters. |

| Water proof | Yes |

| Measurement angle | 75 degrees. |

| Working voltage | DC5V |

| Quiescent current | 5mA |

| Working current | 30mA |

| Working range | 25cm~8m |

| Resolution | 0.5cm |

| Operating temperature | -10~70°C |

| Install Locate | Mount to top of lid |

| Chargers voltage | 110 V |

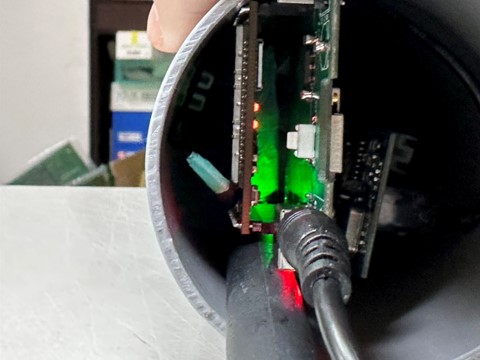

Step 1 : Plug in the power cable to the power and check the name of the sensors.

Step 2 : Wait 30 – 45 seconds for the Tank sensors active. ( active sensors lights must be Green lights).

Step 3 : Check the website tomortdata.com and log in to the website to find your own sensors.

Step 4 : See the liquid changes on the website. Every 30 seconds will reset the sensors to make sure the data information is fresh.

The above is the presentation of the website interface.

The above is the presentation of the website interface.

Data analysis of the status of each detected container.

Data analysis of the status of each detected container.

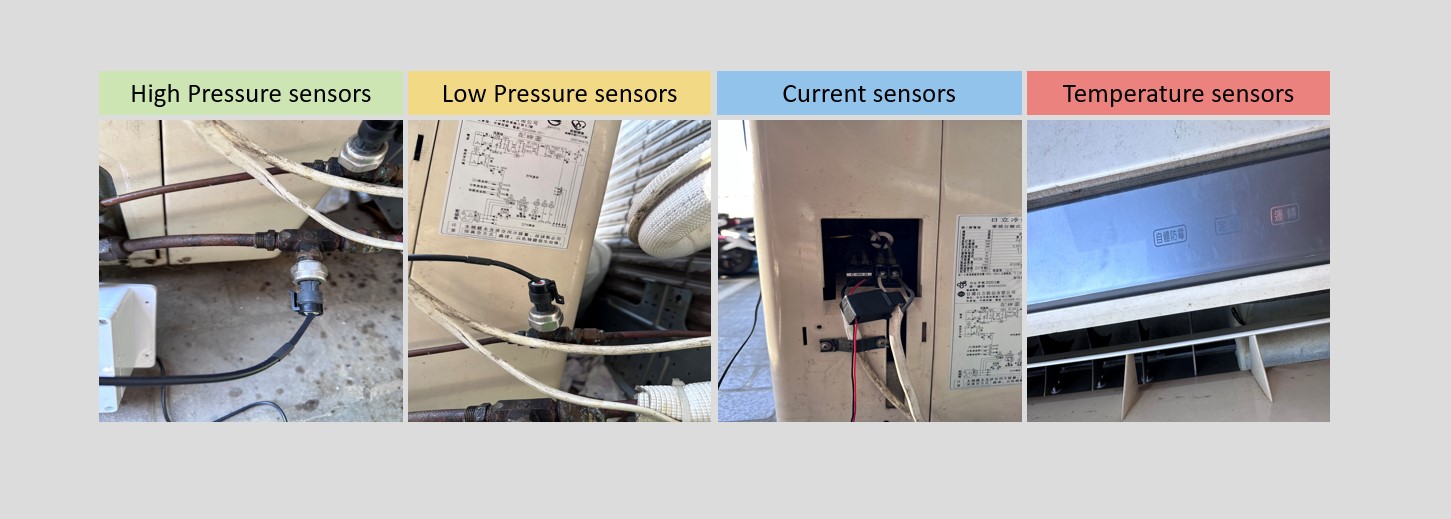

4 Different sensors on the top :

Temperature Sensors

Current Sensors

High Pressure Sensors

Low Pressure Sensors

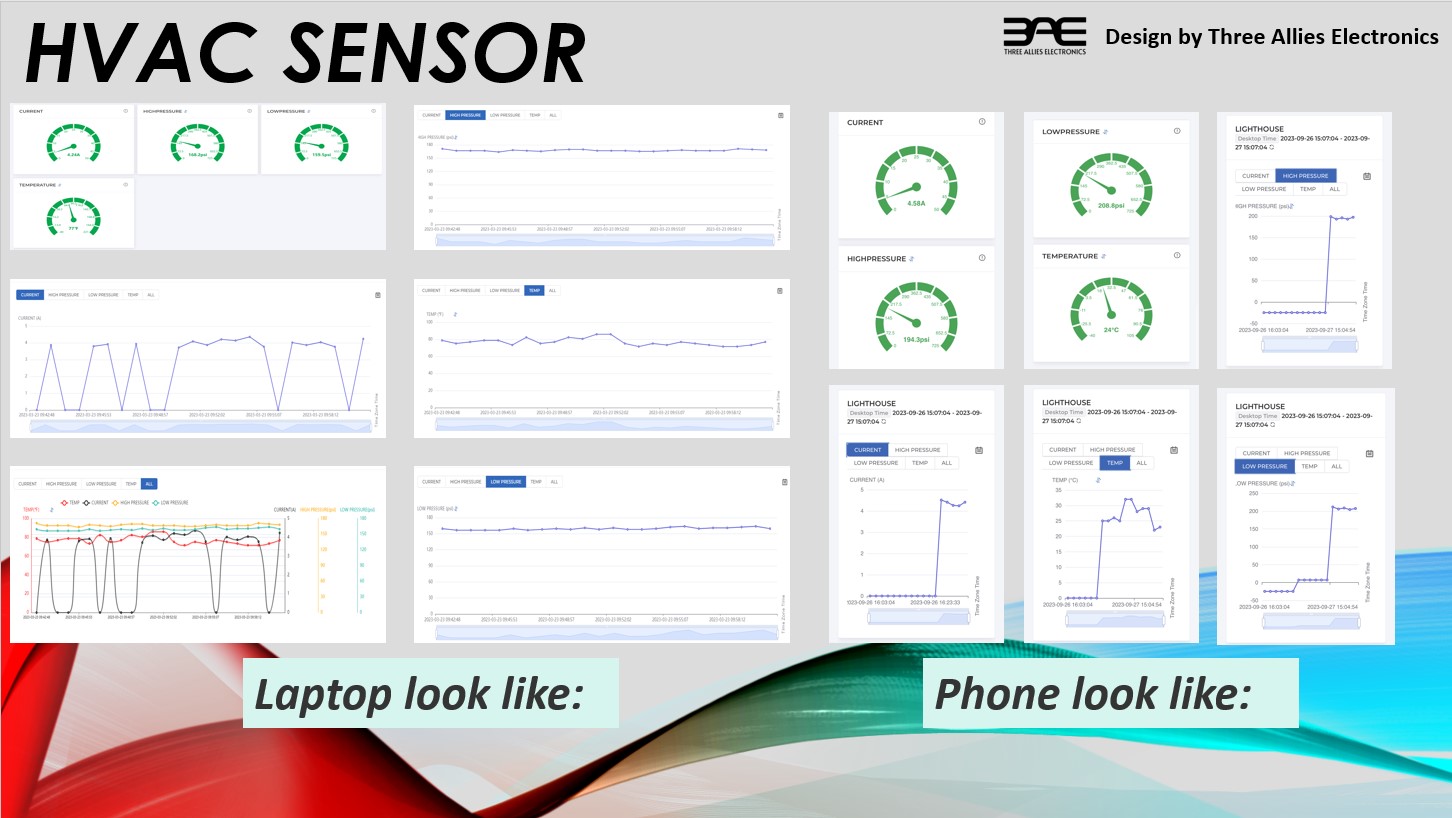

This HVAC sensor is a four-in-one sensor:

It includes sensors for current, temperature, high pressure, and low pressure.

Allows remote monitoring of detection status:

It utilizes 4G communication network for data transmission.

Can replace manual inspection of air conditioning units by human labor.

Simultaneous Detection of Multiple Sensors:

Capable of simultaneously detecting and monitoring multiple air conditioning units..

Enables data analysis:

Detection status can be known through the website

Easy to operate:

Saves time in troubleshooting issues.

| Temperature | -40-125 degrees |

| Current | 50Hz-1KHz |

| Pressure | 0-725psi |

| Installation method | hanging |

| Core material | ferrite |

| Comply with standards | GB20840-2014 |

| Working temperature | -25℃~+60℃ |

| Storage temperature | -30℃~+90℃ |

| Frequency range | 50Hz-1KHz |

| Electrical strength | 3.5KV 50Hz 1min |

| Operating voltage | 5.0 VDC |

| The output voltage | 0.5-4.5 VDC |

| Working current | ≤10 mA |

| Working pressure range | 0~5 MPa |

| Maximum applied pressure: | 7.5 MPa |

| Destroying pressure | 10.0 MPa |

| Range of working temperature | -20~85℃ |

| Storage temperature range | -20~85℃ |

| Measurement error | ±3.0 %FS |

| Protection level | IP65 |

| Response time | ≤2.0 ms |

| Cycle life | 1,000,000 pcs |

Step 1 : Locate the corresponding connection points for the sensors, such as high-pressure and low-pressure pipes, current sensors, and the air conditioning vent. (The location may vary for each air conditioning unit).

Step 2 : Connect the sensors to the designated positions as shown in the diagram.

Step 3 : Turn on the air conditioning unit and the sensor's power to activate them.

Step 4 : Using your smartphone or computer, go to the following website and log in:System Login

Step 5 : In the website, locate the sensors you have set up.

Step 6 : Allow 2-3 minutes for the sensors to transmit data, and confirm their proper functioning after the data has been uploaded.

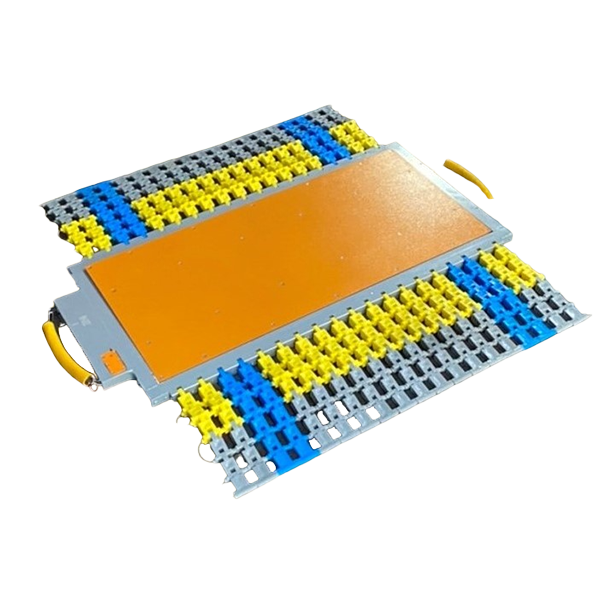

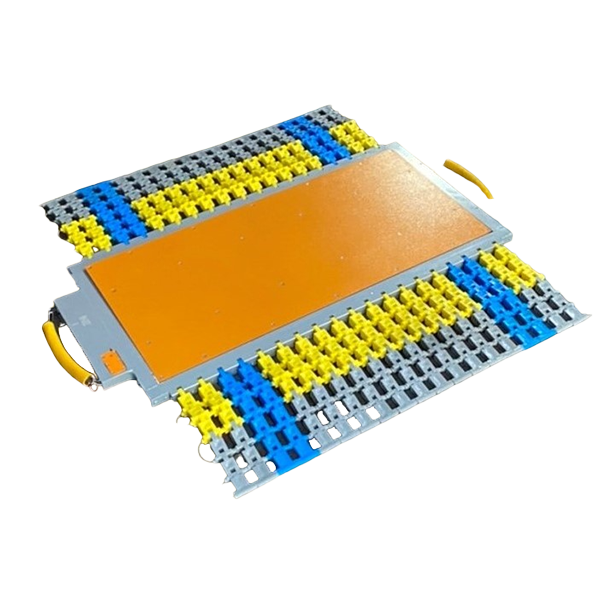

Product Appearance:

Our platform scale is made of aerospace aluminum material, known for its durability and resistance to impact. There are guide slopes both above and below the sensor to provide cushioning.

Sensor Features:

The sensors used in our electronics scales are high-precision sensors with an accuracy of one-thousandth. The installation of sensors inside the scale employs a special embedded method to ensure precision even in harsh environments.

Smart Viewing:

Our platform scale data is recorded in the cloud, eliminating the need for paper printouts. You can easily check the weight with just a tablet!

| Accuracy | Static: + 0.1 - 0.3%F.S / Dynamic: + 1 - 3%F.S; |

| Operating Temperature Range | -30°C to +70°C |

| Weighing Speed | <5 Km/H |

| Safety Overload | 150% |

| Operating Humidity Range | <90% RH |

| Power Supply Voltage | DC 12V |

| Weight of Platform Scale Sensor | 30 kg/piece |

| Sensor Dimensions | 870*470*22mm |

| Protection Measures | Intelligent battery level detection, automatic shutdown when the battery is low. |